can you put wood in a kiln

With a kiln you can control the environment such as temperature humidity and steam levels for a set period of time. Kiln-drying however can cause the wood to shrink.

Everything You Need To Know About Kiln Dried Wood In A Nutshell

50-hour cycles and each time we put 18 tonnes into a kiln and take 12 tonnes out therefore removing 6 tonnes 6000 litres of water.

. Put Your Bench Near a Window. After we get the wood from a covered but open shed and plane the wood it is then put in a room with a dehumidifier for a couple of days. Itll be noticeably heavier than.

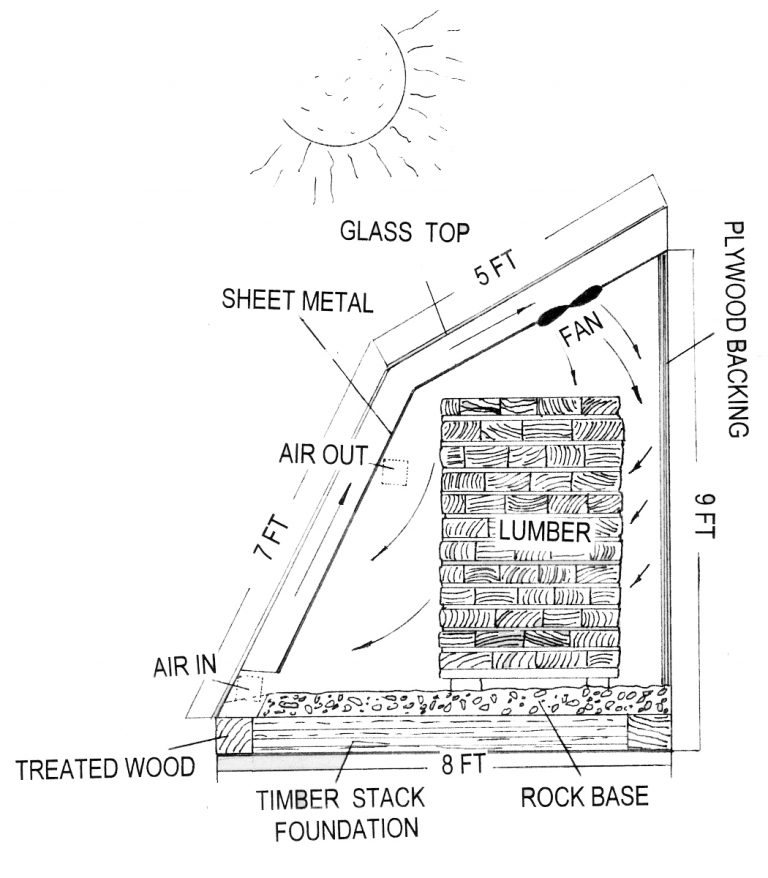

Delivering to all BH and DT postcodes as well as some BA SP TA and EX we cover as much of the South as we can so whether youre in Bournemouth Dorchester Weymouth Yeovil or further afield your logs are hand delivered by our own two man team and placed exactly where you want them. Yes you can stain treated wood right away using exterior oil or water-based stain IF it was already Kiln dried at the lumber yard. Fans should blow towards the front of the kiln away from top vents.

We deliver heat logs peat wood pellets and kiln dried wood direct to your door and you can order from us 365 days a year. This process doesnt introduce any internal tensions in the wood. Confirm it was already dried by looking at the tag or stamp.

If youre cooking a smaller cut of meat or you want just a hint of. It relies on predation parasitism herbivory parasitody or other natural mechanisms but typically also involves an active human management role. Kiln-dried lumber can be expensive.

A kiln is a thermally insulated chamber a type of oven that produces temperatures sufficient to complete some process such as hardening drying or chemical changesKilns have been used for millennia to turn objects made from clay into pottery tiles and bricksVarious industries use rotary kilns for pyroprocessingto calcinate ores to calcinate limestone to lime for cement and to. Store Wood Near the Entrance. If you have been looking for logs for sale then look no further.

Clean the Sap off the wood with a Solvent first. Dont go for the kiln dried stuff however as its more prone to breakage. By Eric Meier Allowing lumber to passively sit at a given humidity level in order to obtain a desired EMC air-drying may be the simplest and least expensive method of seasoning wood but it is also the very slowest.

Made in the USA from kiln-dried Oregon cedar a durable and naturally rot-resistant wood these raised beds are sturdy and easy to assemble. The kind of stain you put on your deck and when you apply it depends on the type and condition of your treated wood. Our kilns can dry wood in approx.

One option is for woodworkers to air dry green wood. Pine and fir are the worst offenders. When the drying is done in a kiln the product is known as kiln-dried timber or lumber whereas air drying is the more traditional method.

Six months is usually enough. A flexible delivery service you can rely on. Woodworking When wood is used as a construction material whether as a structural.

A common question and the answer is yes but only if burnt on an open fire which has no air control but it. Temperature can exceed 150 degrees F inside the kiln so avoid fans with plastic parts that could melt. Natural light not only makes it easy to see what youre working on it makes for a more pleasant working environment.

Drying times can vary significantly depending upon wood species initial moisture level lumber thickness density ambient conditions and processing techniques. Kiln-dried wood is wood that has been dried in an oven kiln. You can easily improve your charcoal grill with the addition of high-quality smoking wood chips.

It is then left in one. Can you stain treated wood right away. Typically multispeed metal window fans are used.

Air-drying is a natural process that can take up to 8 -16 months depending on the species of wood. Kiln-drying on the other hand usually takes 6 8 weeks. Likewise keeping lumber in dark and damp conditions can impede the process.

Cooking with real wood is the only way to get that authentic smoky flavor youre seeking. Also one of the biggest problems is to find the right inspiration and DIY furniture projects that you can make right from. Wood drying also seasoning lumber or wood seasoning reduces the moisture content of wood before its use.

Kiln dried wood can contain as little as 5 water and it is more expensive. This is probably the best option for wood that you can get but it is a little pricier than pressure treated. Our kiln dried logs are made from Ash and other fantastic hardwoods for multi-fuel burners firewood stoves and open fires.

Unlike BBQ chunks wood chips are much smaller and best used for quick bursts of smoke. The entire weight of the boat the friction of motion can put too much stress on certain points. Usually I put one in the wood burner to start with to get things going and then carry on the fire with logsService and delivery was spot on have recommended them to others who have said the same thing.

Its modernized traditional style results in a timeless design while adding lots of storage with 2 large Louvered doors and two spacious 8 14 deep drawers. Kiln Drying Your Own Wood. This is a real mixed bag here.

Our kiln dried logs can be used in your fireplace log burner garden wood fire or pizza oven. Pitmasters generally prefer wood that is airdried and 25 to 30 water. Air drying however can take several months and will generally not achieve a low enough MC without the additional step of.

Therefore woodworkers may want to dry their own wood to help assure they are getting the MC they want. Raise the kiln off the ground with cinder blocks or railroad ties or construct a cement foundation. Your workbench is the place you will likely spend most of your time so why not have it located in a spot that gives you a nice view out the window.

Made of 100 solid pine wood this customizable wardrobe features a sturdy construction that can last for years. Therefore costing you more. This luxurious-looking Shaker Wardrobe Armoire has what it takes to give your bedroom that refined touch.

Dry wood is much lighter there are cracks and splits and the bark is usually loose. Featuring lots of storage with 2 large doors and two spacious 8 14 deep drawers and made of 100 solid pine wood this customizable wardrobe is built with sturdy construction that can last for years. Kiln drying wood to 170 F will crystallize most of the sap and prevent oozing.

There are two main reasons for drying wood. You can generally count on pressure treated wood to dry naturally within a couple months but sometimes the process can take longer in cool damp locations. To be absolutely sure you can use a moisture meter to check the moisture content of the wood.

A heat source is necessary and can be as simple as a portable electric heater but be sure to isolate the heater in a way that you arent creating a fire hazard. Attractive metal knobs a rich finish and elegant Shaker style. 0830 10 Sep 21.

So you can easily work on it using hand tools. Biological pest control is a method of controlling pests such as insects and mites by using other organisms. It is almost spring season and with it comes whole new ways of redecorating your patio backyard or even entire house.

The most common kind is still wet when you buy it. This coastal-looking armoire has what it takes to give your bedroom that refined touch. Wolmanizing is a patented manufacturing process Wet treated wood.

Classical biological control involves the introduction of natural enemies of the pest that are bred in the laboratory and released into. If you arent able to buy kiln-dried wood then if possible heat the wood with a heat gun until the sap crystallizes then seal the wood with the sealer of choice. Each size comes with corner pins the same height as the bed you order so you can put the raised bed on hard ground or a patio if needed and the tops of the pins will be flush with the top of the bed.

But even though that sounds amazing and we know you like a challenge it also takes a lot of time to prepare everything for remodeling. Does kiln dried wood burn faster. The heat will be enough to dry the lumber but you also can put a small dehumidifier in the kiln to speed the process.

There are three basic categories of green-treated or Wolmanized lumber. If you see KDAT kiln-dried after treatment or ADAT air-dried after treatment then stain it right away. Put wood chips in a foil pouch or make a smoke bomb elsewhere on this page.

Drying Wood At Home The Wood Database

My Wood Drying Kiln Wood Kiln Corner Wood Stove Kiln Dried Wood

Solar Dried Lumber Moisture Concerns Solar Kiln

Buying Live Edge The Top 5 Questions To Ask Before You Buy Live Edge Slabs The Wood Cycle Of Wisconsin

Curious To Know If Any Of You Have A Solar Kiln Have You Ever Used It To Season Fire Wood Looking To Build One Would Like To Use It For Slabs And

Solar Kiln Popular Woodworking

Drying 650 Bf Of Walnut In A Homemade Kiln R Woodworking

Buying Live Edge How Long Does It Take To Produce A Quality Live Edge Slab The Wood Cycle Of Wisconsin

Basics Of Solar Lumber Drying Oklahoma State University

A Simple Approach To Drying Lumber Woodshop News

7 Ways To Build A Kiln For Pottery Easy Diy Kiln Ideas

Building A Solar Wood Drying Kiln Grit Wood Kiln Solar Kiln Wood Shed

What Is Kiln Dried Lumber And How Is It Used When Building A Home

What Is Kiln Drying The Reasoning Behind Drying Wood

Kiln Dry Wood At Home Step By Step Method Garden Tool Expert

Diy Drying Kiln Or Dumb Waste Of Time Page 2 Hearth Com Forums Home

What Is Kiln Drying The Reasoning Behind Drying Wood

Drying Wood In The Oven The Ultimate How To Guide Theplywood Com